Soil Stabilization

The use of soil-cement can be of great benefit to agencies responsible for building and maintaining roads. Its cost compares favorably with that of granular-base pavement. When built for equal load-carrying capacity, soil-cement is almost always less expensive than other low-cost site treatment or pavement methods.

The use or reuse of in-place or nearby borrow materials eliminates the need for hauling of expensive, granular-base materials; thus both energy and materials are conserved.

ECONOMIC, ENVIRONMENTAL, AND ENGINEERING BENEFITS

Soil-cement has many benefits, including:

Low first cost—Soil-cement is often more economical to construct than granular bases because the soil material is found on or near the paving site. Generally, any in-place nonorganic, low-plasticity soils can be used. Also, nearby granular borrow soil can provide an excellent material source, requiring lower cement contents than clay and silt soils. Borrow soils do not have to be expensive base-course material; almost any granular material is suitable.

Fast construction—Modern methods and equipment make soil-cement processing simple and efficient. In-place soils are processed at the paving site. When borrow soil is used, it is usually mixed in a central plant at the borrow source, then hauled to the paving site to be compacted, finished to grade, and cured. There is no mellowing period or other delays in the construction process. In addition, soil-cement is stable immediately after construction and gains strength rapidly.

Recycling of existing materials— Making good soil-cement out of old flexible pavement is nothing new; it has been done for years. Failed flexible pavements contain materials that can be salvaged economically by recycling—breaking them up, pulverizing them, and stabilizing them with a minimum quantity of portland cement to make a new soil-cement base. There is no disposal problem as is commonly found when old pavements are dug out. Since approximately 90% of the material used is already in place, handling and hauling costs are cut to a minimum. Many granular and waste materials from quarries and gravel pits also can be used to make soil-cement, thus conserving high-grade materials for other purposes.

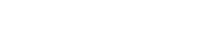

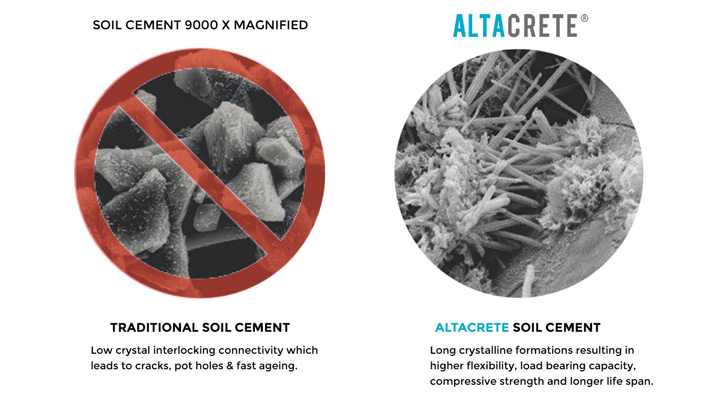

Stiffness—Soil-cement is a low-cost pavement base offering the feature most essential for long-lasting parking areas and roads: stiffness. Large paved areas must maintain their original grade and must not develop depressions or potholes if they are to drain freely during rains, thereby preventing puddles and damage from water that seeps through and weakens the underlying soil. The stiffness of a cement-stabilized base acts to distribute loads over a wider area, reducing subgrade stresses and allowing the base to maintain its original grade for many years without costly resurfacing or repairs.

Soil-cement does not rut or consolidate. As a cemented material, it does not soften when exposed to water. When rutting occurs in an unstabilized base material or the underlying subgrade soil, a simple overlay of the pavement surface is insufficient to correct the cause of the rutting. With a stabilized base, rutting is confined to the asphalt surface layer and is relatively simple and less expensive to correct.

This low cost has made soil-cement an attractive alternative to designers of roads and pavements. In addition, soil-cement has considerably more load-carrying capacity than flexible pavements, requiring less thickness to carry a given load. Pavement engineers praise soil-cement’s performance, its low first cost, long life, and high strength. Soil-cement is constructed quickly and easily—a fact appreciated by local government agencies and the traveling public.